3D Printing in Stimuli-Responsive Yield-Stress Fluid with an Interactive Dual Microstructure

Scientific Achievement

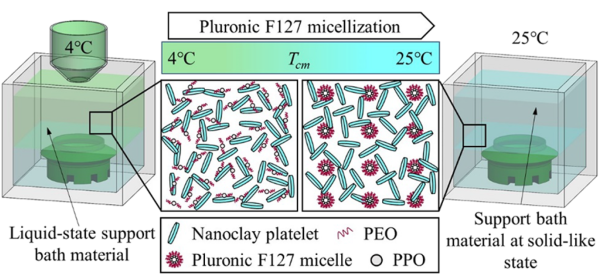

It was shown that 2% Laponite nanoclay and 30% Pluronic F127 form an interacting dual microstructure in aqueous solution, with high yield stress of 554.2 Pa at 25 °C, and low viscosity approximately 1 Pascal-second at 4 °C.

Significance and Impact

This work shows how technical limitations of support bath assisted 3D printing can be overcome via temperature cycling of dual microstructure nanocomposite systems.

Research Details

- Structures of dispersed Pluronic-coated Laponite at 4 °C and Laponite house-of-cards assembly embedded in Pluronic micelles colloidal crystal at 25 °C were determined by small-angle neutron scattering (SANS).

- Additional properties were determined by measurements of dynamic shear-stress, viscosity, differential scanning calorimetry and electron microscopy.

- Viability of the system was demonstrated by 3D printing of various artifacts.

“Three-Dimensional Printing in Stimuli-Responsive Yield-Stress Fluid with an Interactive Dual Microstructure”

Weijian Hua, Kellen Mitchell, Lasith S. Kariyawasam, Changwoo Do, Jihua Chen, Lily Raymond, Naima Valentin, Ryan Coulter, Ying Yang, and Yifei Jin

ACS Applied Materials & Interfaces 14, 39420 (2022). DOI: https://doi.org/10.1021/acsami.2c12465