HFIR Pressure Vessel Replacement Project

The High Flux Isotope Reactor (HFIR) is a versatile, high-performance nuclear research reactor that provides world-class scientific capabilities in several key mission areas essential to U.S. scientific competitiveness: neutron scattering, isotope production and materials irradiation. HFIR offers these unsurpassed capabilities because it is the brightest time-averaged cold and thermal neutron source for neutron scattering experiments. Its highest thermal neutron fluxes, or outputs, enable production of isotopes for a diverse set of applications, and many of these isotopes are produced only by HFIR for the western world. These higher outputs provide the greatest impacts per atom, which enables accelerated damage studies on advanced reactor fuels and materials for use in future fission and fusion reactors.

The reactor pressure vessel must be replaced

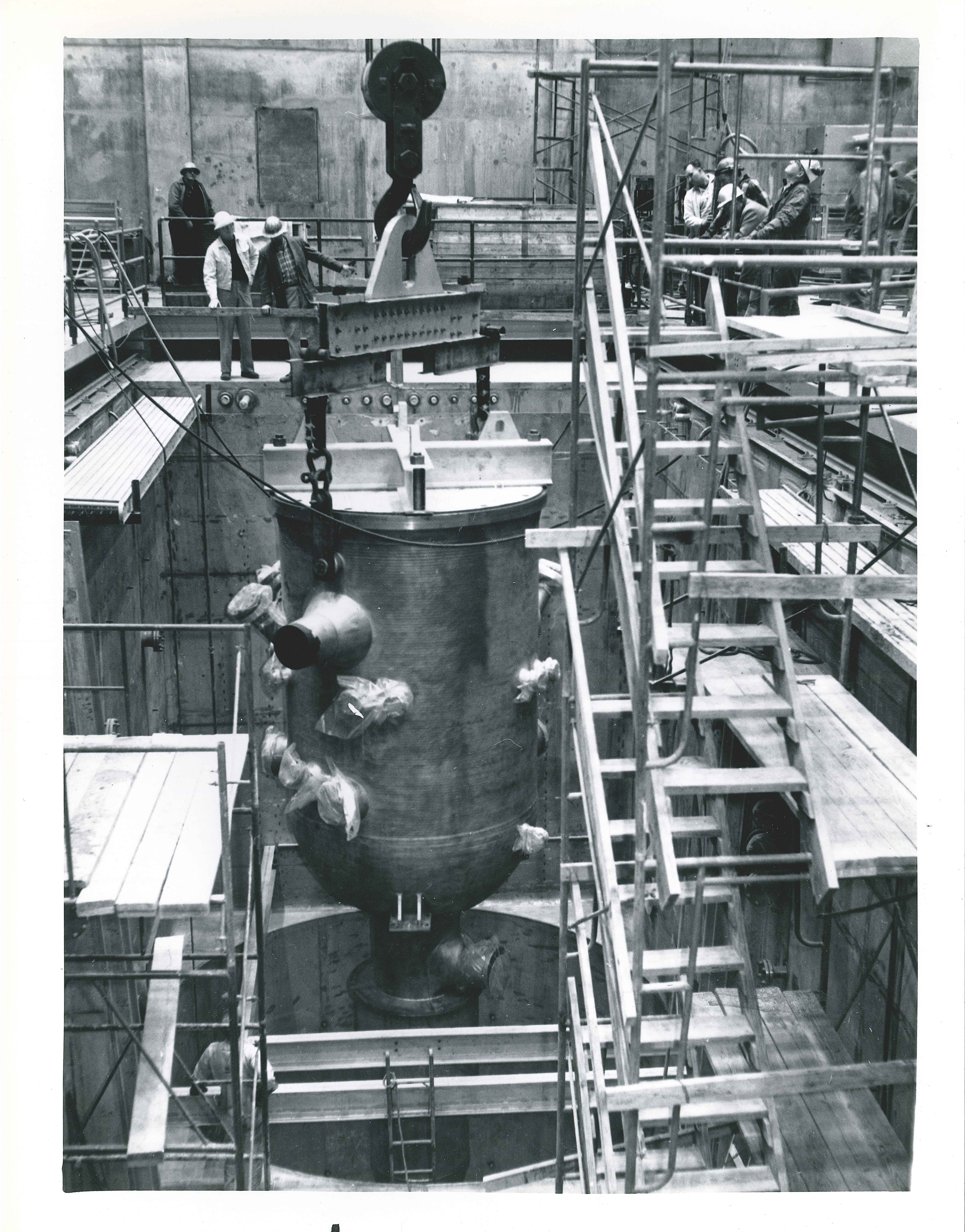

HFIR, completed in 1965, includes components that need periodic replacement, such as the reactor pressure vessel (PV). The pressure vessel contains the reactor, which runs at 85 megawatts (MW) thermal energy and is cooled with a flow of 16,000 gallons of water per minute.

In the 1980s, HFIR’s carbon steel PV was found to be more brittle than anticipated because of the radiation environment. Since then, the reactor’s operating power has been reduced from 100 MW to 85 MW to slow the embrittlement and extend the reactor’s operating lifetime. Owing to HFIR’s importance in a myriad of applications spanning energy, automotive safety, healthcare, homeland security, future computing technologies and planetary exploration, it is imperative to ensure the long-term availability of this vital national resource. Replacing the pressure vessel will allow a return to 100 MW operation.

A feasibility study performed in the 1980s concluded that the HFIR pressure vessel could indeed be replaced. Furthermore, modest design changes to the PV could enable significant future enhancements to the HFIR mission and increase HFIR’s scientific impact. In 2020, a U.S. Department of Energy Basic Energy Sciences Advisory Committee (BESAC) subcommittee issued the report, “Scientific Justification for a U.S. Domestic High-Performance Reactor-Based Research Facility,” [1] recommending that ORNL pursue replacement of the HFIR PV immediately. In 2020, DOE confirmed the need for maintaining HFIR operations.

Original HFIR pressure vessel installation in 1965.

A two-phase PV replacement project

The project will be performed in two distinct phases. Phase One will involve the design, construction and delivery of the PV to ORNL. Although the current PV is expected to maintain its integrity into the 2050s, beginning work on the PV early will mitigate the risk of the premature shutdown of the HFIR facility. Preliminary estimates indicate that the new PV could be delivered to ORNL in the mid-2030s.

Phase Two will involve the installation, alignment and commissioning of the reactor PV. The timeline for the project is under active development, but the PV replacement would likely occur in the late 2030s or early 2040s. The project team is currently: (A) pursuing the design of a new vessel using material that is not as susceptible to radiation embrittlement and allowing resumption of operations at 100 MW; (B) actively exploring design concepts that would enable future scientific mission enhancements (e.g. improvements to neutron scattering, isotope production and materials irradiation); (C) pursuing the early conceptual design of the new vessel including reconstituting the original reactor design drawings; and (D) developing a safety design strategy.

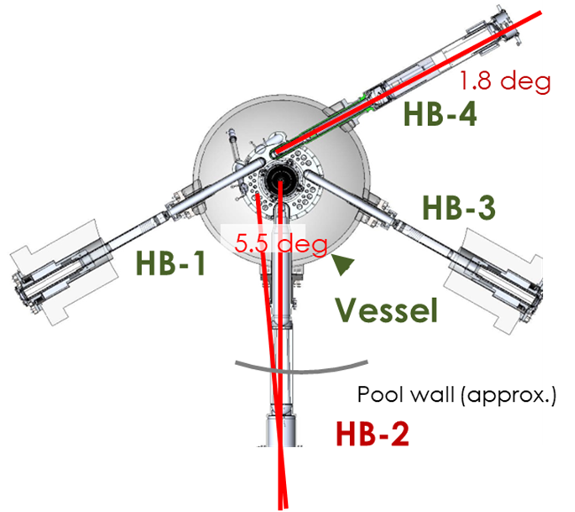

Conceptual drawing of the HFIR reactor pressure vessel and neutron beam tubes showing possible design modifications to the pressure vessel that would enable future scientific enhancements. Rotating beam tube HB-4 by a small amount would allow future improvements to the cold neutron instrument suite. Rotating the HB-2 beam tube and converting it from a radial beam tube to a tangential beam tube, would enable a future, low-background guide hall downstream from the confinement building.

[1] Report of the Basic Energy Sciences Advisory Committee, “The Scientific Justification for a U.S. Domestic High-Performance Reactor-Based Research Facility,” 2020.