If a journey of a thousand miles begins with a single step, then the Proton Power Upgrade (PPU) project’s journey to 2.8 megawatts of power began with a giant stride—about 1.3 miles in length. That’s how much new stainless steel piping was installed—smoothly and accurately—thanks in part to the project team’s use of building information modeling, or “BIM,” practices.

The PPU project underway at Oak Ridge National Laboratory (ORNL), planned for early completion in 2025, will double the Spallation Neutron Source (SNS) linear accelerator’s available power from 1.4 MW to 2.8 MW, requiring upgrades to many of the accelerator’s supporting systems. One area, the klystron gallery, will contain 28 additional klystrons (a klystron is an electron beam tube used to power the accelerator’s cryomodules) and radio-frequency systems, which will generate more heat than in the past.

Consequently, a new and more powerful cooling system is needed to provide enhanced cooling for the project’s expanded klystron gallery and to help maintain desired operating conditions.

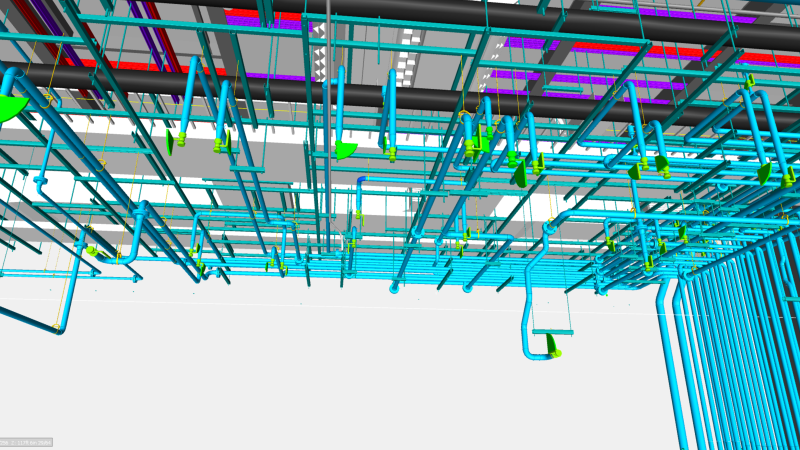

Prior to construction, the PPU design team used a BIM program to plan the complex layout and routing of the cooling system pipes. BIM enables planning, generating, and managing digital images of physical and functional characteristics of components and systems in a physical space.

BIM procedures permit virtually building a facility prior to its actual physical construction, which reduces uncertainty, improves safety, helps work out problems, and simulates and analyzes potential impacts. The system also provides “clash detection” by visually identifying where conflicts could exist between separate systems once they are installed together onsite.

Subcontractors can access critical information from the BIM model long before construction begins, which in the case of the klystron gallery cooling system permitted the pipe contractor to fabricate the individual pipe sections off-site before they were installed in the klystron gallery.

“The hundreds of individual pipe sections were like pieces of a puzzle that had to be installed in a pre-planned sequence to permit fitting them into confined spaces,” said L2 Manager for PPU Conventional Facilities Mark Connell. “The largest pieces were installed first and then the smaller pieces had to be nested around them.”

Connell added the cooling system was designed to maximize the number of welds and minimize the number of flanges to reduce potential leak points. Also, to provide easier access to the waveguides, the cooling pipes were installed above the guides.

This section of the new klystron gallery cooling system shows the

high level of precision and craftsmanship required for the project.

The new cooling loop includes 7,000 linear feet (about 1.3 miles) of stainless steel piping, consisting of hundreds of individual sections of pipe, ranging from half-inch diameter up to the main supply headers that are 10 inches in diameter. Through this system chilled water will flow at a rate of up to 1,500 gallons per minute—enough to fill a large in-ground pool in under 10 minutes. Deionized water is used to help avoid mineral deposits and damage from corrosive salts.

In addition to doubling the power of the linac’s proton beam, the upgrade will permit a broader range of pulsed neutron beam experiments at the First Target Station that complement the continuous neutron beam experiments at ORNL’s High Flux Isotope Reactor (HFIR). Eventually, the upgraded linac will also power world-leading neutron research at the Second Target Station that will be built at the SNS site.

“Despite needing to take precautions due to the pandemic, the complex installation of the klystron gallery cooling system was completed without major incident,” said John Galambos, PPU project director. “I’m proud of the way the team stayed focused and was able to keep working despite some very challenging circumstances.”

As part of the project, a new pump room was added to building 8300 and adjacent to 8340 to house two new and more powerful 150-horsepower water pumps.

After completion, the klystron gallery project was turned over to the installation subcontractor for radio-frequency equipment installation and fit-out. For more information, visit https://neutrons.ornl.gov/ppu.

SNS and HFIR are DOE Office of Science user facilities. ORNL is managed by UT-Battelle LLC for DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. DOE’s Office of Science is working to address some of the most pressing challenges of our time. For more information, visit energy.gov/science. – Paul Boisvert