Manufacturers often face a dilemma: whether to use conventional steel that is easily joined by traditional welding methods, or use lighter, high-strength steel that reduces weight and adds durability, but can be challenging to weld.

Now scientists in the Oak Ridge National Laboratory (ORNL) Materials Science and Technology Division (MSTD) have collaborated with JFE Steel Corporation on using ORNL’s friction stir spot welding (FSSW) technology to join overlapping sheets of JFE’s advanced high-strength steel.

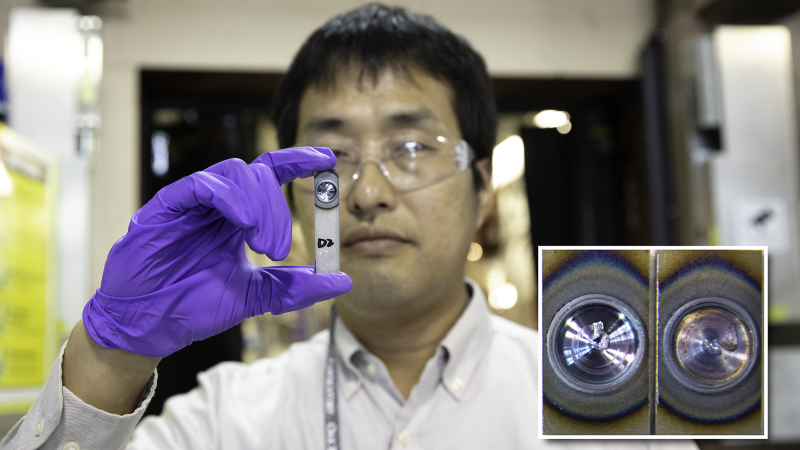

FSSW involves applying downward pressure on a rotating tool that is plunged into overlapping metal sheets, which produces frictional heat to soften—but not melt—the metal under and around the tool. The softened metal is “stirred” together to create a solid-state bond at the interface after the tool is withdrawn. A circular “onion ring” pattern remains on the surface of the metal, which can be covered or removed during finishing.

The result of FSSW is an extremely strong spot weld that retains the strength and other properties of the original bulk material. Such welds eliminate the added weight of fasteners and avoid causing structural weakening and other defects associated with the high-temperature melting and resolidification of fusion (arc) welding. Like friction stir welding (FSW), used to produce linear welds, FSSW works well for joining similar and dissimilar materials.

“Our friction spot welds have demonstrated acceptable overall properties when we evaluated them using destructive testing methods,” said Koichi Taniguchi, senior researcher in JFE’s Steel Research Laboratory. “However, we want to more accurately quantify residual stress and changes in the steel resulting from thermal and mechanical changes during the friction welding process. For this, we chose to use neutrons at ORNL because of their nondestructive qualities and ability to penetrate solid metals.”

The scientists used the SNAP pressure diffractometer at ORNL’s Spallation Neutron Source (SNS) for its ability to image the sample welds at different depths, which enabled creating a high-resolution 3D reconstruction of the welded material for detailed analysis.

“Our goal for the research is to correlate the microstructure of the welds with welding process variables, such as tool design and rotation speed, plunge depth, and downward pressure on the workpiece, which will help us develop and optimize JFE’s FSSW processes,” said Taniguchi. “It will also improve our fundamental understanding of the materials we use and help us develop entirely new types of steel.”

MSTD Materials Joining Group Leader Zhili Feng said, “The ability to use neutrons as a nondestructive testing system will facilitate JFE’s efforts to develop a reliable concept for predicting the performance of potential new materials during friction welding.”

JFE Steel Corporation and ORNL are collaborating on FSSW research through a Strategic Partnerships Project. The neutron studies were conducted as part of the SNS user program, which is supported by the DOE Office of Science. The initial development of ORNL’s FSSW technology was supported by DOE’s Office of Energy Efficiency and Renewable Energy.

SNS is a DOE Office of Science User Facility. ORNL is managed by UT-Battelle LLC for DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. DOE’s Office of Science is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.–by Paul Boisvert