Massive offshore structures like oil rigs and wind turbines are designed to withstand the myriad punishments oceans tend to mete out. However, over time, just the saltwater itself can significantly decrease the durability of a structure’s welds.

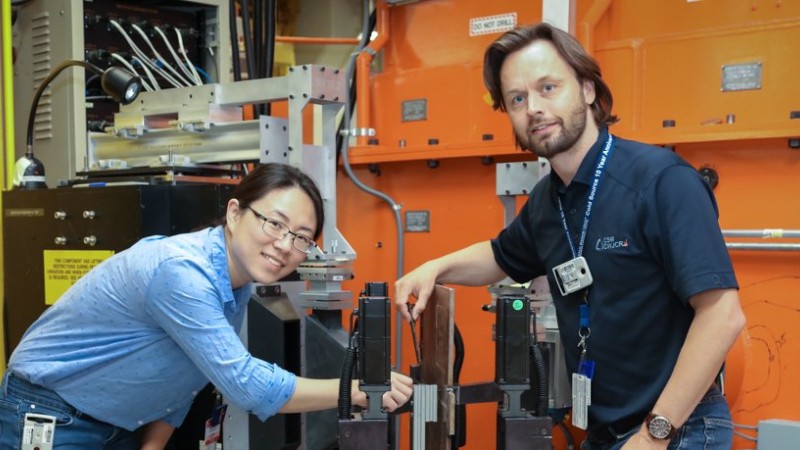

That’s why professors Michael Joachim Andreassen from the Technical University of Denmark (DTU) and Zhenzhen Yu from the Colorado School of Mines are using neutron analysis at the Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) to validate a more advanced method of welding involving high-power lasers. Neutrons have highly penetrating properties—more so than X-rays—and can probe almost any material in a nondestructive fashion.

The Neutron Residual Stress Mapping Facility (NRSF2) at ORNL’s High Flux Isotope Reactor—a DOE Office of Science User Facility—enables researchers to study the quality of their welds at the atomic scale. The team’s findings could lead to faster, more cost-effective production methods, as well as significantly stronger, longer lasting welds.

“We’re studying residual stresses in really huge structures,” said Andreassen, “especially supersized monopiles—enormous steel cylinders that form the underwater foundations for wind turbines. We want to look at the relationship between residual stress and varying thicknesses in the steel plates used in construction, by comparing two different welding methods.”

Andreassen demonstrates the enormity of each steel section used

to build the monopile foundation in which circumferential welds are

used to fuse them together. (Image credit: DTU/Louis Andersen)

In general, residual stresses are stresses that remain in the weld’s structure after applied loads or pressures have been removed. In some cases, residual stresses can lead to premature failures like cracks or leaks. They can be caused by several factors, such as fluctuations in temperature, exposure to harmful chemicals, or metal fatigue, caused by repeatedly applied loads.

The steel plates used to build monopiles can be up to 130 millimeters thick, said Andreassen. They are typically welded together using a traditional method called submerged arc welding, where electric arcs are used to melt the joining materials. Therein, the weld’s molten seam, or weld pool, is continually “submerged,” or covered, in a granular flux of various compounds used to support the weld and protect it from atmospheric contaminants.

As shown, the submerged arc welding features a significantly

As shown, the submerged arc welding features a significantly

wide groove with high inherent residual stresses.

(Image credit: DTU/Daniel Sommerlund Pedersen)

There are a variety of benefits to submerged arc welding. Among other things, the technique produces fewer impurities, sparks, and toxic fumes than similar methods. However, says Andreassen, there are significant burdens, too.

“You have to remove a lot of material to do the weld, and then add filler material after. It costs a lot to remove and add the materials, and in the end, you have a really huge groove with lots of introduced residual stresses,” he explained.

Naturally, the more tensile residual stresses there are, the more susceptible a weld will be to failure.

“The hybrid laser-arc welding technique introduces a more focused heat source that allows us to mitigate residual stress,” said Yu. “In the ocean, saltwater eventually creates corrosion, and if you have high degrees of tensile residual stress, the faster corrosion occurs and the greater the likelihood of fractures or cracks propagating through welded regions.”

Neutrons provide an extraordinarily detailed picture of how the atoms are behaving deep inside the welds, comparing residual stresses from both the submerged arc and hybrid laser-arc samples. The neutron measurements show any changes in residual stress as Andreassen and Yu increase the steel plate sample sizes from 10 to 20, 40, and 60 millimeters thick.

“The reason we like neutrons for this research is because it’s the only technique that can penetrate through the steel plates to give us a complete profile of the residual stress,” said Yu. “We will use the neutron data and compare it with simulation work from Michael’s group that we can apply directly to the actual structure.”

HFIR is a DOE Office of Science User Facility. UT-Battelle manages ORNL for the DOE’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit http://science.energy.gov/.—by Jeremy Rumsey