Neutrons at work for GE Research

The penetrating power of neutrons at Oak Ridge National Laboratory (ORNL) helped GE Research study magnetically patterned metal layers deep inside its unique electric motor for signs of warping and residual stress, without damaging the prototype.

Neutron data indicated there are significant, unevenly distributed residual stresses, which agreed with GE’s calculations. The results of the analysis will be used to establish design rules to avoid warping and minimize distortion during high-temperature production.

Neutrons easily penetrate thick, dense materials

Studies show neutron diffraction is ideal for studying residual stress, because neutrons easily penetrate and distinguish among different phases in thick, dense materials, including metals—and can still observe internal fluids and gases in real-time.

The researchers used ORNL’s VULCAN engineering materials diffractometer beamline, the world’s premier neutron instrument for studying large industrial devices—even inside operating combustion engines—and bulk materials.

For more details, visit

https://neutrons.ornl.gov/content/ornl-scientists-help-ge-develop-a-unique-%E2%80%98magnetic-motor%E2%80%99

Contact

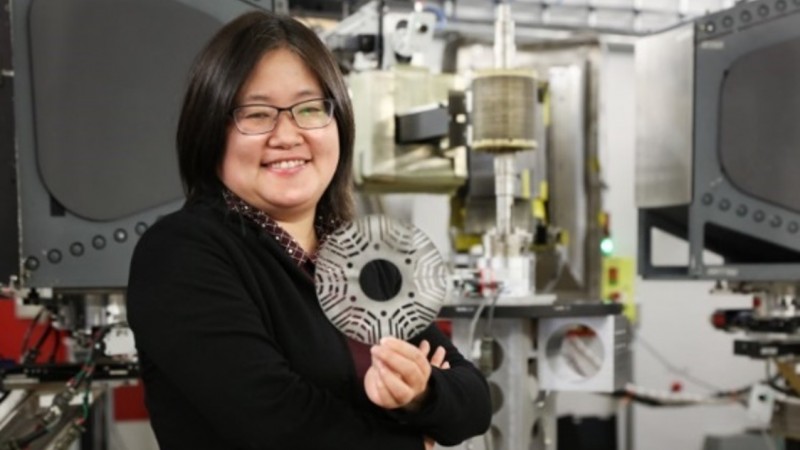

Dr. Ke An

Industrial Liaison

kean@ornl.gov