Orientation Dependence of Deformation Damage in Al Alloys

Scientific Achievement

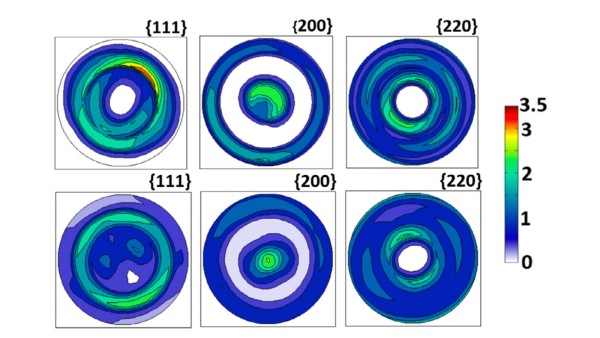

It was shown that during mechanical deformation, aluminum alloy grains oriented with the stiffer <111> directions parallel to the applied load accumulated more damage.

Significance and Impact

Based on this detailed understanding of orientation dependence, manufacturing processes can be modified to produce improved structural materials through optimization of the crystallographic microstructure.

Research Details

- In-situ neutron diffraction was conducted on commercial Al alloys.

- Relaxation of the effective elastic constants was directly observed in deformed samples.

- Grains oriented along a “hard direction” accumulate more damage than soft ones, as predicted by crystal plasticity modeling.

“Crystallographic orientation and spatially resolved damage in a dispersion-hardened Al alloy”

Qingge Xie, Junhe Lian, Jurij J. Sidor, Fengwei Sun, Xingchen Yan, Chaoyue Chen, Tingkun Liu, Weijian Chen, Ping Yang, Ke An, and Yandong Wang

Acta Materialia, 193, 138-150 (2020).

DOI: https://doi.org/10.1016/j.actamat.2020.03.049