Hydraulic fracturing contributes significantly to US energy production. It works by tapping hard-to-reach pockets of oil and natural gas where more traditional drilling methods fall short. However, the process requires large amounts of water and chemicals, which can negatively impact public health and the environment.

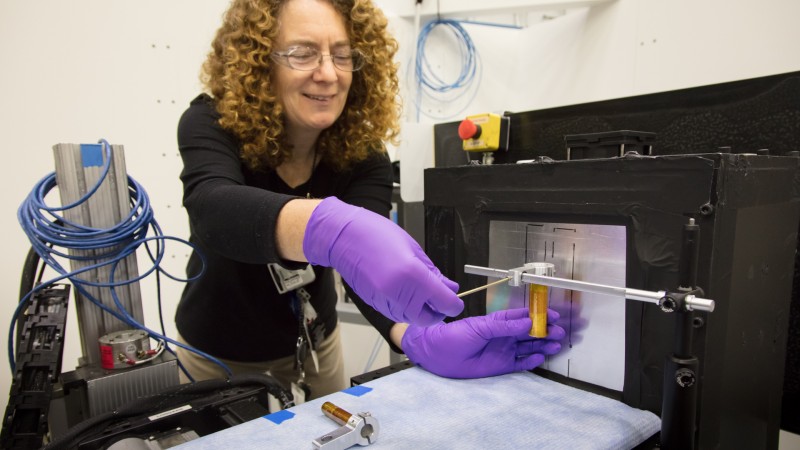

A team of researchers at the Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) are using a combination of neutron and x-ray scattering to make the process safer and more efficient. They want to improve hydraulic fracturing, or fracking, by blasting well surfaces, or bores, with acoustic energy, which would enhance the ability of fracking to penetrate fractures in wells and drastically reduce the amounts of water and chemicals needed.

“There’s tremendous benefit for fracking oil and gas wells with less chemicals and water,” said Richard Hale, a researcher in ORNL’s Nuclear Science and Engineering Directorate investigating whether acoustic energy can be used for that purpose.

Hale says the idea is to alter the essential structure of a well with ultrasonic vibrations to allow oil and gas to flow more effectively. Primarily, acoustic energy hasbeen used to clear away debris in and around the surface of the well, but Hale and the team want to take that concept to the next level to see if acoustic energy can alter the porosity and permeability of formations far below the surface to reach more isolated pockets of oil and natural gas.

“It's all about supplying energy into the formation to release hydrocarbons,” explained ORNL researcher Joanna McFarlane.

“Think of a sponge filled with water,” Hale added. “The water doesn’t come out of the pores until you squeeze it. Acoustic energy is really, really good at squeezing these pores. In small core sample–size experiments placed in acoustic baths, we can see the oil flows easily and rapidly from the rock.”

Neutron imaging reveals in situ fluid flow behaviors in shale and limestone via an optimized fracturing

method using acoustic waves. The three vignettes illustrate the comparison between acoustic fractured

and unfractured limestones; the complexity of flow patterns in shale during acoustic stimulation;

and the complexity of the shale fracture network when mapped in 3-dimensions.

Neutrons are uniquely able to penetrate deep into materials, making them perfect for the kind of experiments the team wants to perform. Using the Cold Neutron Imaging beamline CG-1D at ORNL’s High Flux Isotope Reactor (HFIR) allowed the team to study fundamental interactions at the atomic scale. When the ore samples are placed in a bath of water and exposed to ultrasonic vibrations, images made from neutron data show the researchers in unprecedented detail how the fluids react to and move through the pores in the rock.

“HFIR is like a great big flashlight, and with that big flashlight—that big steady stream of neutrons—we can see the interaction between fluids and structures more clearly,” Hale said.

Hale also notes that conducting the research at ORNL gives theteam access to leading experts in a plethora of complementary fields, making his research group a world-class team of distinguished scientists and engineers.

“The wonderful thing is no matter what idea you have, there’s somebody here at the lab who’s an expert. You just have to find them,” he said. “I mean, this whole thing started during a lunch-break conversation.”

Hale says investigating this concept would not be possible without expertise in fields as varied as geology, neutron science, x-rays, and ultrasonic acoustics.

Analyzing the fluid and structural dynamic data generated from the experiments can be computationally demanding. For improved analysis, JeanBilheux, from ORNL’s Neutron Data Sciences, developed software using Jupyter Notebook, an open-source programming platform that allowed the team to visualize and interact with the data shortly after experimentation concluded.

“The Jupyter Notebooks greatly facilitate data analysis,” McFarlane said.“Although we can observe changes in the shale samples in real time in the radiographs, it will be the quantitative results that will gain us future funding.”

In addition to Hale and McFarlane, the research team includes Stephen Oliver, Ayyoub M. Momen, Bruce Patton, Larry Anovitz, Philip Bingham, and the beamline staff at the HFIR CG-1D Imaging Instrument—Hassina Bilheux, Jean-Christophe Bilheux, and Paris Cornwell.

If the team can successfully demonstrate that acoustic energy is a viable method for fracking, they hope to find an industry partner who could help them take the idea into the next phase of development.

The research was supported by DOE’s Office of Science, Office of Basic Energy Sciences, Chemical Sciences, Geosciences, and Biosciences Division.

HFIR is a DOE Office of Science User Facility. UT-Battelle LLC manages ORNL for the DOE Office of Science. The single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.—by Gage Taylor