Rising from the icy depths of the Crystal Sound in Antarctica, two prominent landmarks sit side by side amid the natural wonders of this frozen frontier.

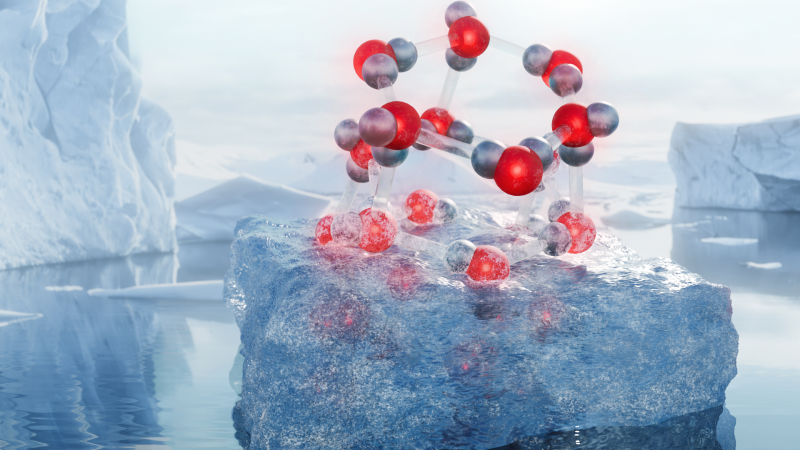

Shull Rocks, a chain of low, snow-covered rocks, and neighboring Wollan Island, a dome-shaped, ice-capped isle, were named in 1960 for Clifford Shull and Ernest Wollan: two visionary researchers who together in the 1940s pioneered the field of neutron scattering. Fittingly, the two men are honored at one of the coldest places on Earth, in part, for their help in determining the molecular structures of many materials, including ice crystals.

Just five years later, thanks in part to Shull and Wollan’s early neutron research and the world’s growing interest in producing heavy elements and their isotopes, construction was completed on another landmark — the High Flux Isotope Reactor at Oak Ridge National Laboratory. Since first achieving criticality in 1965, the reactor’s fission process has produced a continuous supply of neutrons that enabled making transuranium elements, valuable isotopes, and groundbreaking discoveries by materials researchers from around the world.

As part of celebrating HFIR’s 60th Anniversary, this article summarizes the circumstances that led to the initial need for HFIR and its subsequent expanding role during its decades of enabling world-class research and serving the nation and the world.

Competing in the post-World War II era

After the role scientists played in helping end World War II in 1945, the public and governments around the globe became aware of the many world-changing opportunities presented by scientists — specifically physicists.

Worldwide, throughout the 1950s and 1960s, the race was on to develop nuclear technologies, not only for defense but also for all sorts of new applications, such as energy for powering homes. Famously, in a 1954 speech, the chairman of the U.S. Atomic Energy Commission promised the public that nuclear-generated electricity would soon be “too cheap to meter.”

At the same time, interest in nuclear medicine had been growing. Radioisotopes, or more commonly, just “isotopes,” were typically created by exposing materials to neutrons produced in a nuclear reactor. The first recorded use of such medical isotopes to treat a patient occurred around 1936, when researchers used a radioactive isotope of phosphorus to treat a leukemia patient.

By the late 1950s, dozens of reactors dedicated to neutron research, isotope production, nuclear engineering and other pursuits were being developed, particularly in North America and Europe.

1958: HFIR’s story begins

In January 1958, the status of the American isotopes production program was critically reviewed by the AEC. Following this report, the Commission embarked on an accelerated program designed to build and secure supplies of medical and industrial isotopes to meet the nation’s anticipated needs. By November, the agency recommended that a continuous, “high-flux,” or high-output, reactor be designed, built and operated at Oak Ridge National Laboratory, with construction to begin in 1961. Glenn T. Seaborg, a Nobel Laureate for his prior work with heavy elements and AEC chairman from 1961 to 1971, championed the project.

The High Flux Isotope Reactor and a co-located Transuranium Processing Plant, today called the Radiochemical Engineering Development Center, would be built to produce “substantial weighable quantities” of heavy transuranium elements and their isotopes.

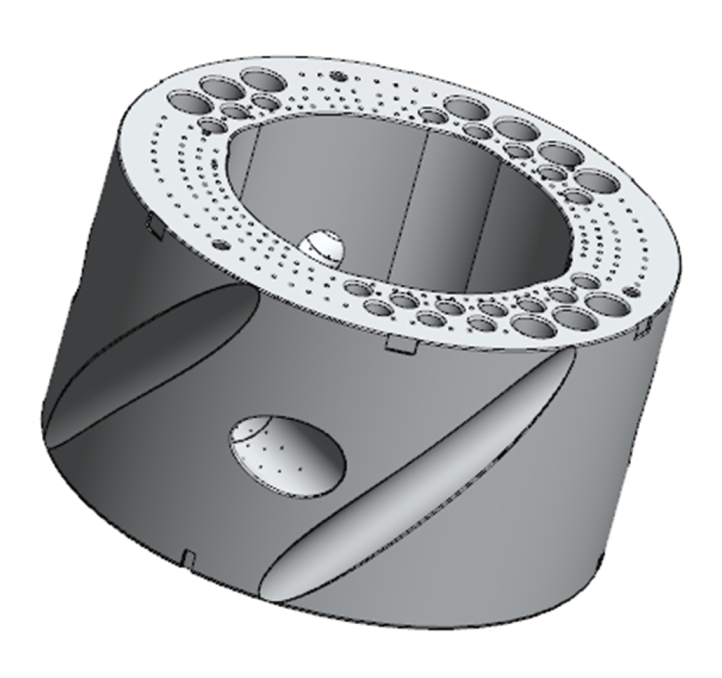

Originally, HFIR was intended only for producing those heavy elements and isotopes as well as for materials research. It would not produce electricity. The reactor was designed based on the “flux trap” principle, in which enriched uranium reactor fuel is surrounded by a ring of beryllium metal approximately 12 inches thick. Neutrons emitted from the fuel are reflected back toward the reactor core by the beryllium, which produces a region of highly concentrated neutrons that scientists can use for experiments.

The design included 22 vertical holes drilled into the top of the beryllium reflector to hold materials for irradiation that are later retrieved, analyzed and used as isotopes. Today, a pneumatically operated system also provides access to HFIR’s neutrons for short-term irradiations using small capsules, or “rabbits,” to shuttle samples in and out of the reflector while the reactor is operating. A second rabbit facility can insert capsules into the flux trap area for isotope production and materials studies.

Wisely, during the design stage, then-Laboratory Director Alvin Weinberg insisted that four ports leading from the reactor core be installed to accommodate future beam tubes, each capable of supporting multiple neutron research instruments. Weinberg wanted the ports to eventually enable expanding the Lab’s neutron scattering program — to remain competitive with other nations — by supporting more advanced scattering experiments using HFIR’s planned 100-megawatt capabilities.

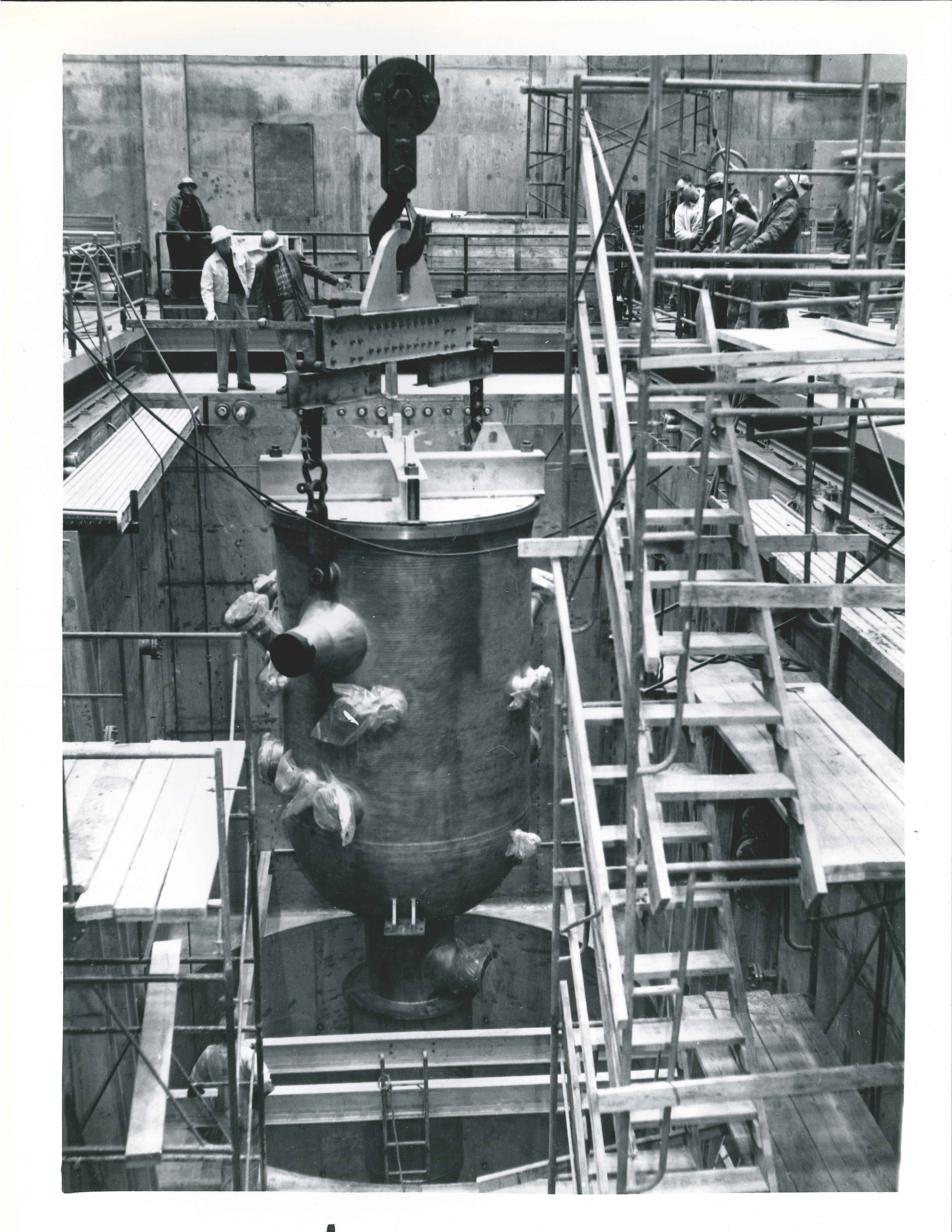

1961-1964: HFIR construction

After more than two years of extensive planning and design, HFIR’s construction began in June 1961 on a site south of ORNL’s main campus.

Building the reactor and cooling tower cost $14.7 million ($150 million in 2025 dollars), and HFIR’s first operating budget totaled approximately $2.3 million ($23.6 million in 2025 dollars). Successful expansion of the reactor’s operations, capabilities and staff over the years can be seen in its fiscal 2025 budget, standing at just over $100 million to support 236 personnel.

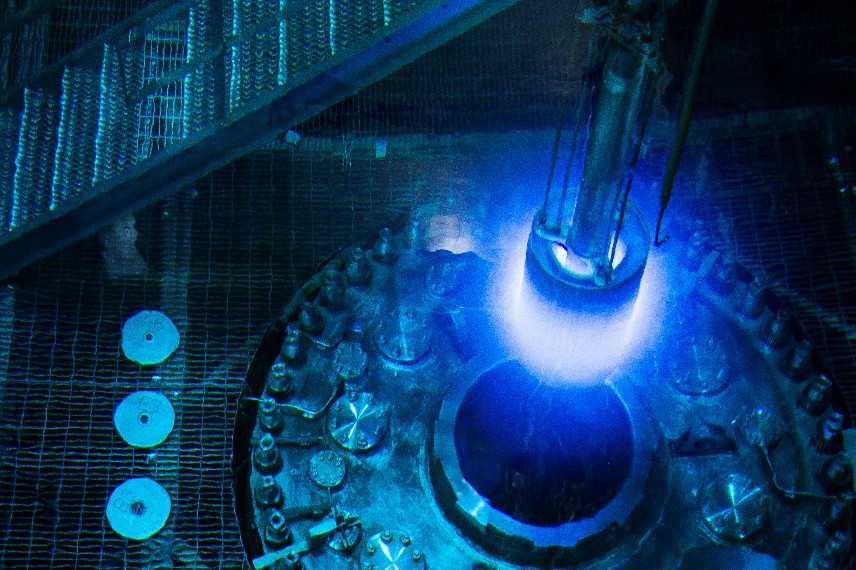

1965: HFIR achieves its first criticality

With construction complete, the final hydraulic and mechanical testing began. Criticality was first achieved on August 25,1965.

The low-power testing program was completed in January 1966, and in September HFIR began operating at its full 100 megawatts of power. For the next 20-plus years, HFIR was operated predominantly for transuranium element and isotope production, until the main focus changed to neutron scattering.

Highlights from HFIR’s isotopes program

Since it first began operating, HFIR has served as one of the world’s primary sources of valuable isotopes for a wide range of applications, such as:

- Californium-252 for cancer treatments and other uses

- Plutonium-238 for powering NASA space missions

- Berkelium-249, which enabled the discovery of Tennessine, element 117

- Actinium-227 for targeted alpha therapy to treat cancer

- Tungsten-188 for treating malignant cancers and rheumatoid arthritis

- Selenium-75 for inspecting industrial welds and other nondestructive testing

- Nickel-63 for electronic surge protectors, nuclear batteries and detecting explosives at airports

The neutron scattering program at HFIR was first managed by a prominent research group of about 100 employees, of which neutron research involved just a handful of distinguished scientists. Among these were Wallace Koehler, Mike Wilkinson, Ralph Moon and Herb Mook, all of whom had worked closely with Cliff Shull. While the division’s initial focus was studying radiation damage in solids, this was later extended to neutron scattering in materials. — Jaime Fernandez-Baca, ORNL neutron scientist (1986-2024)

HFIR’s role expands

The science of neutron scattering had been evolving since its inception in the 1940s by Clifford Shull and Ernest Wollan. Together they developed the first neutron diffraction techniques. Bertram Brockhouse, who is widely credited with developing neutron spectroscopy, would ultimately share with Shull the 1994 Nobel Prize in Physics for their accomplishments. Unfortunately, Ernest Wollan was not eligible for the Nobel because he had died 10 years earlier.

By the late 1960s, the United States was in a strong position in the physical sciences, due in part to major advances in isotope production and neutron scattering research on materials. Research reactors in Britain, France, Germany and Holland were also making great strides, but the American flagship sources, including HFIR, were performing some of the highest-impact research, particularly in condensed matter physics and chemistry.

In the 1970s, scientists at HFIR began putting some of the reactor’s overabundance of high-energy neutrons inside the flux trap to good use by conducting materials irradiation experiments on samples of steels and other materials intended for use in future fission and fusion facilities. They found that in certain cases, one year of irradiation at HFIR was roughly equal to five years of irradiation in other fission reactors, so HFIR experiments significantly shortened the time it took to get the needed data. Some longer-term experiments at HFIR have been running in real time for about 20 years, which, if needed, could provide a half century or more worth of data on how radiation exposure affects those materials.

Demand for irradiation experiments remains high, so ORNL’s Irradiation Engineering group works to increase throughput, in part by developing more efficient reactor components to increase the number of experiments that can be safely irradiated at HFIR. Advanced Reactor Demonstration Programs require many material samples to support their research and development efforts, which are designed to provide advanced reactor companies the data needed to convince regulators to let them start up their reactors.

During the next two decades, advances in HFIR’s instrumentation and operations expanded its capabilities in isotope production and neutron scattering to study and develop a wider variety of materials. Examples of scientific advances enabled by HFIR:

- Determining the magnetic structures and behaviors of rare earth metals

- Measuring magnetic behaviors in 3D metals

- Measuring the Bose condensate fraction in liquid helium

- Measuring phonons in technologically important materials, such as graphite

- Determining the magnetic form factors from paramagnetic metals

- Developing the neutron polarization analysis technique

- Identifying phonon anomalies in superconductors

- Discovering phonons and magnetic behaviors in high-temperature superconductors

- Producing a radiopharmaceutical heart-imaging agent that could detect how much of a patient's heart muscle was still alive after a heart attack

- Completing the first small-angle neutron scattering instrument in the United States

HFIR has long been a source for irradiating materials to push them to their limits — to the point where their microstructures change. These experiments provide detailed characterizations of how radiation affects materials’ properties.

Early on, most of the neutron science was driven by the interests of the ORNL staff scientists, which were fairly narrow. But as the User Program grew, it really diversified the HFIR scientific portfolio because there is a lot you can do with neutrons. — Bryan C. Chakoumakos, Corporate Fellow Emeritus, ORNL neutron scientist (1987-2024)

HFIR: A DOE user facility

Since the early 1980s, HFIR has served as a valuable Department of Energy multi-mission user facility. The construction and operation of such large-scale scientific user facilities has been integral to the mission of the DOE from its earliest days.

In a typical year, about 500 researchers access HFIR’s neutron instruments either by visiting in person or using the instruments remotely. These users have helped extend neutron scattering research across a wide range of applications while contributing to the public and scientific community. In the past, their experiments have studied and helped develop materials for many new technologies.

1986: A pause for safety

In 1986, shortly after the Chernobyl reactor incident, ORNL began internal reviews of all of its research reactors to identify potential safety deficiencies and plan corrective actions. These reviews eventually led to HFIR’s shutdown in November of that year. Additional internal and external reviews prompted a DOE order that all ORNL research reactors be shut down until needed improvements — primarily in management and procedures — could be made. For the first time in its history, the laboratory had no operating nuclear reactors.

During the shutdown, routine testing indicated HFIR’s neutron radiation was embrittling the reactor pressure vessel at a faster rate than predicted. More than three years later, following a thorough reevaluation and implementing modifications to protect the integrity of the pressure vessel, the reactor was restarted and resumed operations at a reduced power level of 85 megawatts.

Coinciding with HFIR’s restart in May 1990 was a renewed emphasis on staff training, safety analyses and quality assurance activities, while long-term commitments were made for continued technological and procedural improvements.

At that time, DOE also mandated that ORNL form a separate reactors division. Consequently, the Research Reactors Division was chartered on April 6, 1987, with the primary goal of developing more reliable reactor operations.

1993: HFIR superconductor measurements

During most of the 1990s, HFIR operated at 85 megawatts — from its restart to the beginning of the beryllium reflector replacement outage in 2000. Many innovative and exciting experiments were performed during this period.

Most visible was HFIR’s involvement in groundbreaking energy research into high-temperature superconductivity. This research yielded the first polarized neutron measurements of magnetic excitations in yttrium barium copper oxide, a family of crystalline compounds that display some properties of high-temperature superconductivity.

Around the same time, HFIR played a crucial role in increasing the production of the medical isotope strontium-89, which was used to alleviate pain in patients suffering from metastatic bone cancer. The FDA-approved radiopharmaceutical accumulated in bones, where it released cancer-fighting beta particles to enhance patients’ quality of life.

One big challenge at HFIR in the 1990s was the diminishing space in the HFIR pool that stores spent fuel elements. Research Reactors Division personnel designed and installed new storage racks to increase the amount of available space in the pool. In the late 1990s, a spent fuel shipping cask was procured and shipments of spent fuel to a DOE site began for storage and future disposition.

2000: HFIR expands to meet future science challenges

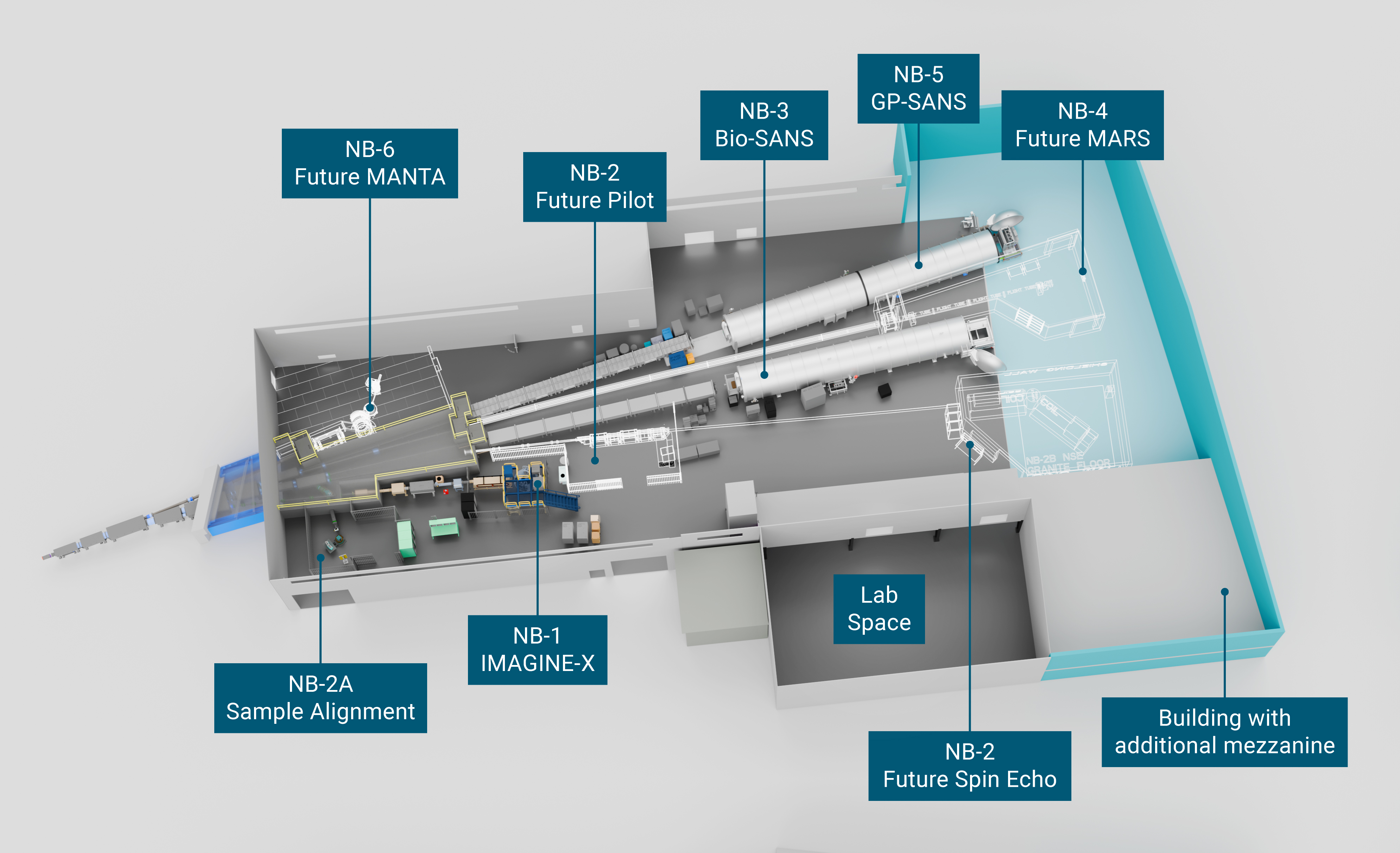

A major upgrade and expansion of HFIR started during a planned outage in 2000. The original cooling tower was replaced, and a redesigned beryllium reflector and associated cage were installed to allow for larger beam tubes. Construction began on expanding HFIR to the south by adding a Cold Guide Hall that would house eight additional neutron instruments for research using “cold neutrons” — neutrons with lower energies.

The expansion was needed because cold neutrons have longer wavelengths and lower energies, making them ideal for measuring material properties at longer length scales and excitations with better energy resolution than is possible using conventional thermal neutrons. This expansion enabled studying larger structures in biological systems and quantum materials.

HFIR was restarted in 2001 after the beryllium reflector was replaced, and construction of the Cold Guide Hall was completed in 2003. Its novel cold source, completed in May 2007, was a first-of-a-kind cryogenic neutron source that operated at a temperature of 20 kelvin (about ten times colder than the South Pole). The HFIR cold source project proved to be a huge success, supplying a cold neutron intensity comparable to the world’s best.

HFIR in the 21st century

The newly upgraded and expanded HFIR raced into the new millennium. Cold Guide Hall instruments attracted new users who wanted to conduct a wider range of experiments, which helped lead to exciting developments, such as the discovery of a treatment for COVID-19.

2006: The Spallation Neutron Source (above) came online to provide a complementary, world-leading pulsed neutron source. ORNL’s neutron scattering program was moved to the newly created Neutron Sciences Directorate.

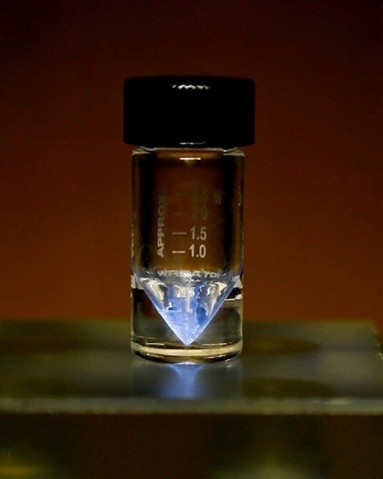

2010: After 250 days of irradiation, 22 milligrams of berkelium-249 (such a quantity could only be made at HFIR) was used to produce the heavy element 117, which was named Tennessine to honor the contributions of ORNL, Vanderbilt University and the University of Tennessee.

2014: HFIR was declared a Nuclear Historic Landmark by the American Nuclear Society in recognition of 50 years of operations supporting research and development of heavy actinides and other isotopes and its continued importance to the United States for neutron scattering research and national security.

2016: The reactor achieved 1.0 million megawatt-days of operation. This power level is equivalent to operating HFIR every day for 32 years at 85 megawatts.

2020: Plutonium-238 was produced at HFIR and used on Mars to power NASA’s Perseverance rover (above). ORNL established what is now the Isotope Science and Engineering Directorate devoted to isotope research and production.

2021: Scientists using neutrons at HFIR found an unexpected interaction between a hepatitis C drug and the SARS-CoV-2 virus. This discovery helped advance efforts to develop a treatment for COVID-19.

2024: DOE funds the construction of the U.S. Stable Isotope Production and Research Center, a facility to enrich stable isotopes at ORNL

2025: Chevron USA published the results of its researchers working with HFIR scientists to use small-angle neutron scattering experiments to look at nanoporosity in sedimentary rocks, as well as shales and coal, that trap natural gas and oils.

HFIR leads the way

In addition to its initial purpose of producing heavy element isotopes for industrial, medical and research applications, HFIR’s mission has expanded significantly over the years to include the following:

- Supporting neutron scattering and imaging materials research

- Producing a wider variety and larger quantities of isotopes

- Developing medical isotopes for worldwide uses

- Irradiating test materials to evaluate the effects of radiation exposure

- Inducing neutron activation (radioactivity) in materials to identify their composition, such as for nuclear nonproliferation agencies

- Serving as a test bed supporting the search for sterile neutrinos

- Providing the DOE Fusion Energy program with tests on ceramics and other materials

- Enabling images of gas bubble formation inside an operating fuel injector to benefit the automotive and aerospace industries

Expanding the Cold Guide Hall

Plans are underway to extend HFIR’s Cold Guide Hall toward the south by more than 4,000 square feet to permit reconfiguring and optimizing the existing instruments and to add new instruments.

The expansion will include an upgraded cold source, new beam tube alignments, and a new shape and orientation for the guide hall footprint.

The existing user instruments will all be reinstalled at optimized positions for improved performance, and a position for a new high-performance neutron spin echo instrument will be created. Overall, the calculated flux gain for a typical experiment is between a factor of 1.3 and 3.0 for all HFIR instruments, except for the C-TAX instrument, which expects an increase in flux by a factor of 30 or higher.

Time again to replace HFIR’s beryllium reflector

The beryllium reflector helps drive neutron production by reflecting stray neutrons back into the core as they are generated. After more than 20 years of successful operation, HFIR’s existing reflector is approaching the end of its service life. Therefore, ORNL is planning to replace the reflector, along with other reactor core components, to sustain and enhance HFIR’s operational performance.

The HFIR Beryllium Reflector Replacement project will feature a new design for the reflector and beam tubes to optimize neutron scattering, isotope production and irradiation experiments as well as enable legacy waste removal and cleaning out the storage pool.

ORNL will also take the opportunity presented by the HFIR Beryllium Reflector Replacement outage to implement a series of upgrades that will enhance and increase HFIR’s science capabilities.

The carbon steel used in the original HFIR pressure vessel, which contains the reactor, the heart of HFIR, is slowly becoming embrittled by the intense radiation. In the next few decades, we need to perform heart transplant surgery to replace the pressure vessel. This will result in a fully modernized HFIR that will continue offering world-class performance well into the next century. — Matthias Frontzek, ORNL neutron scattering scientist

The reactor pressure vessel must be replaced

ORNL is also preparing to replace HFIR’s pressure vessel and other key reactor components.

HFIR is still running safely and reliably with the original reactor pressure vessel installed in 1964. The pressure vessel contains the reactor core and other vital components needed for reactor operation.

Because of HFIR’s importance in many applications spanning energy security, automotive safety, healthcare, homeland security, future computing technologies and planetary exploration, the long-term availability of this vital national resource must be maintained. In addition to preserving availability, replacing the pressure vessel will allow a return to 100-megawatt operation.

Although the integrity of the existing pressure vessel is expected to last into the 2050s, beginning work on replacing it now will mitigate the risk of a premature HFIR facility shutdown. Preliminary estimates indicate that a new pressure vessel could be delivered to ORNL in the mid-2030s and installed by the late 2030s or early 2040s.

HFIR has produced a long history of excellent science, and it's remarkable that it has remained at the forefront. It's still a vital part of the nation’s plan for going forward in neutron science. It’s also fitting that the future of neutron research is taking shape at ORNL, the birthplace of neutron scattering, to leverage all of the lab’s institutional knowledge, experience, supporting systems, engineers and technicians.

— Stephen Nagler, Corporate Fellow Emeritus, ORNL neutron scientist (1995-2023)

Paul Boisvert