Researchers at the US Department of Energy’s Oak Ridge National Laboratory (ORNL) now have access to a cutting-edge capability for studying catalysts.

Catalysts are specialized materials that help facilitate chemical reactions, from refining petrochemical products and purifying gasses to processing fuel and preparing food. According to the North American Catalysis Society, catalysts contribute to more than 35% of the global GDP and represent a $12 billion market in the United States alone. As a result, research on understanding the material properties and optimizing the performance of integral catalysts during industrial processes is a high priority in the scientific community.

Traditional research approaches only examine the catalyst and other products before or after the reaction has taken place. However, a team of scientists from ORNL and Colorado State University recently developed a gas flow cell capable of studying the atomic structure of these materials in real time. Using neutron diffraction and total scattering techniques, experiments can mimic real-world conditions with industrial relevance—like catalytic converters in vehicles—to supply new insights into the impermanent relationship between the catalyst and the reaction products.

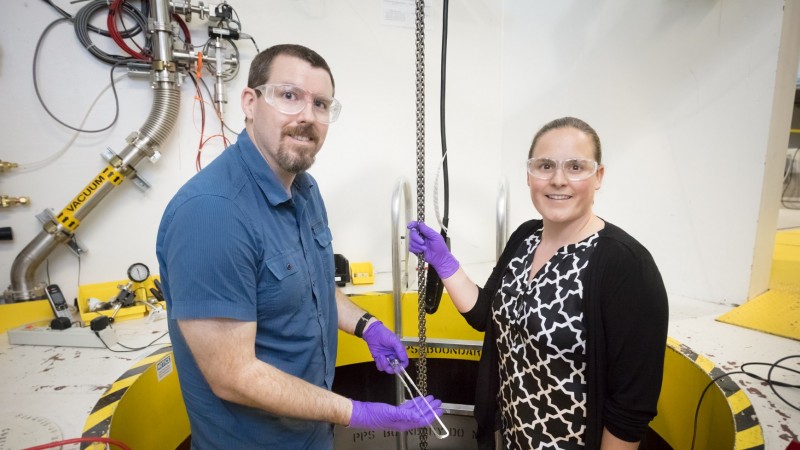

“If we want to understand the limits of current technologies and help design new materials, better materials, we have to understand why they work,” said Daniel Olds, a postdoctoral researcher at ORNL’s Spallation Neutron Source (SNS).

Contributors from SNS and ORNL’s Center for Nanophase Materials Sciences (CNMS) included chemists, instrument scientists, data reduction specialists, and sample environment experts. The project used seed Laboratory Directed Research and Development (LDRD) funds, and both staff and users have already taken advantage of this new capability.

“It’s one of those pieces that was immediately adopted by the community, which is really exciting for our instrument team,” said NOMAD instrument scientist Katharine Page.

By installing the gas flow cell at the high-intensity NOMAD diffractometer, SNS beamline 1B, the team created a new sample environment where users can examine catalytic reactions under realistic operating conditions. The neutron’s ability to differentiate between isotopes was the key to effectively studying gas-solid interfaces between a catalyst and a material sample.

“Diffraction techniques can often probe changes to the catalyst itself, but the interaction of the catalyst with the entity that you’re catalyzing is often very difficult to probe,” Page said.

Because all the isotopes of a parent element have the same number of protons, many analytical methods cannot tell them apart. However, neutron diffraction techniques can differentiate between isotopes as each individual atom has a different number of neutrons. Using neutron diffraction and the steady-state isotope transient kinetic analysis (SSITKA) technique simultaneously, the team studied the interaction of an adsorbing gas with a tubular reactor sample filled with solid particles of the mineral zeolite-X, a common commercial catalyst.

“The techniques we use are uniquely sensitive to the amorphous and transient interfaces in these catalyst materials,” Page explained.

Alternating between different isotopes of nitrogen, the team identified parts of the sample on which to observe gas flow and adsorption through powder diffraction. They established an ongoing flow of nitrogen to help the sample reach a constant reaction state, needed to take SSITKA measurements.

A valve in the flow cell allows switching between different gases so their impacts on the reaction can be observed while a residual gas analyzer measures gas coming off the sample. Combined with results from the diffraction and SSITKA methods, these data helped the team locate areas of interest in their sample while filtering out nonessential information.

“We were able to see this signal that you would be hard pressed to find any other way, and it was not easy,” Olds said.

To make future research easier, Olds developed a new software program called combinatory appraisal of transition states (CATS), which allows researchers to upload hundreds or thousands of data sets at once. The algorithm then provides graphical representations of reactions taking place and helps catch any potential problems at the beamline.

The team initially constructed a complex gas flow cell, but their final design of a simple U-tube shape helps circumvent the engineering issues that can plague more complicated equipment.

“Nothing here came out of a box. It was all custom and had to be integrated together,” Olds said.

The researchers describe their work in a study titled “A high precision gas flow cell for performing in situ neutron studies of local atomic structure in catalytic materials.”

“The gas flow cell LDRD project really generated a whole new class of sample environment capabilities,” Page said.

The research team also included Peter F. Peterson, Jue Liu, Gerald Rucker, Mariano Ruiz-Rodriguez, Michelle Pawel, and Steven H. Overbury from ORNL and Arnold Paecklar, Michael Olsen, and James R. Neilson from Colorado State University.

“As always, it was terrific working with the fantastic ORNL researchers to bring a new idea to fruition through design, build, testing, and use. The LDRD program was a terrific opportunity for us as external users and collaborators,” Neilson said.

This work was supported by DOE’s Office of Science and ORNL’s LDRD Program.

SNS and CNMS are DOE Office of Science User Facilities. UT-Battelle manages ORNL for DOE’s Office of Science. The Office of Science is the single largest supporter of basic research in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit http://science.energy.gov/.—By Elizabeth Rosenthal