Neutron Probes Load Sharing Transients in 3D-Printed Nanocomposite

February 13, 2025

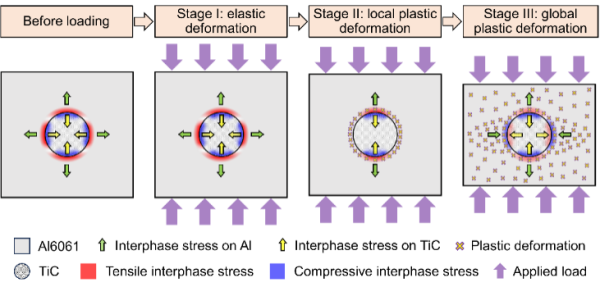

Schematic showing the three-stage deformation mechanism of the additively manufactured Al6061+TiC nanocomposite, which is revealed by in situ neutron diffraction.

Scientific Achievement

Multi-stage anisotropic interphase stress evolution was revealed during deformation of additively manufactured (AMed) TiC-reinforced Al6061 nanocomposites.

Significance and Impact

The understandings of deformation mechanism provide guidance of nanocomposite designs and AM optimizations toward excellent mechanical performance.

Research Details

- Fusion-based AM composited 2%~5% of TiC nanoparticles in Al6061, which increased the strength of the matrix.

- Continuous in situ neutron diffraction captured the dynamic phase-specific behaviors, especially the percentages of TiC.

- TiC refined Al grains, shared load and hindered dislocations movement in Al.

“Multi-stage load partitioning in additively manufactured Al6061+TiC nanocomposite characterized by in-situ neutron diffraction,“ Additive Manufacturing 96, 104584 (2024).

https://doi.org/10.1016/j.addma.2024.104584