Neutrons at work for JFE Steel Corporation

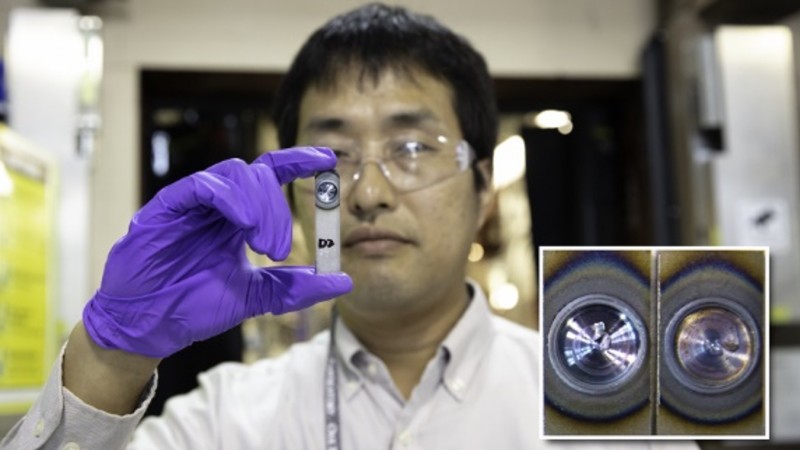

JFE Steel Corporation worked with Oak Ridge National Laboratory’s (ORNL’s) materials scientists to optimize the company’s friction stir spot welding technology used to join overlapping sheets of JFE’s advanced high-strength steel.

The scientists then used ORNL’s SNAP pressure diffractometer to image sample welds at different depths, which enabled creating a high-resolution 3D reconstruction of the welded material for detailed analysis.

Neutrons examine materials non-destructively

The ability to use neutrons as a nondestructive testing system facilitated JFE’s efforts to develop a reliable model for predicting the performance of potential new materials during friction welding.

Neutron data helped JFE correlate the microstructure of the welds with welding process variables, such as tool design and rotation speed, plunge depth, and downward pressure on the workpiece.

For more details, visit: Friction welding cooks up ‘steel onion rings’

Contact

Dr. Ke An

Industrial Liaison

kean@ornl.gov