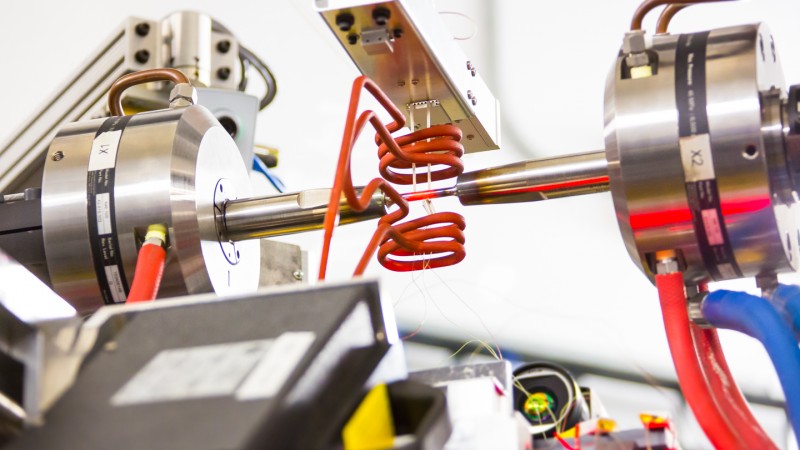

Yan Gao and Shenyan Huang from GE Global Research are using neutron diffraction to study nickel-based superalloys, metals that are commonly used in the hot sections of air and land-based gas turbines, on VULCAN, Engineering Materials Diffractometer, SNS beam line 7. Shown here is the research team’s experimental setup.

The team is working to learn more about the high temperature stability and reliability of this material, specifically the material’s response to creep, or deformation at high temperatures. They are making neutron diffraction measurements on VULCAN under high temperature and high stress.

“Lab testing alone tells us about the overall performance of the material,” explained Huang. “But with neutron diffraction, we can see how the material reacts and responds at both macroscopic and microscopic level, which helps validate property model.”

Gao added, “The really attractive part of using VULCAN is being able to combine microstructure measurements and mechanical testing information in real time to help us make connections to the mechanical behavior of the superalloy.”

They ultimately hope to gather information that will improve the fundamental understanding of why the material behaves differently under different conditions, which will improve future designs.