Neutrons at work for Corning Inc.

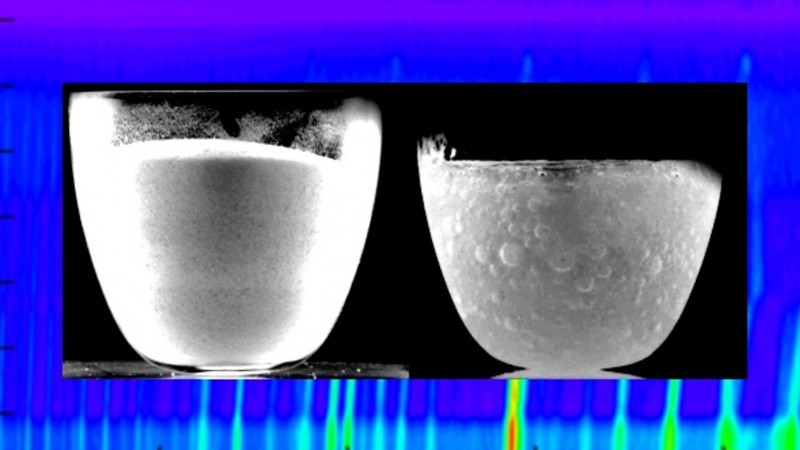

Corning researchers collected data in real-time using an intense neutron beam as sand, alumina and other additives were heated to create glass in a high-temperature sample chamber at the VULCAN engineering materials diffractometer neutron instrument.

The large sampling volume of the VULCAN beamline—located at Oak Ridge National Laboratory’s (ORNL’s) Spallation Neutron Source—provided data much more representative of reactions in a multi-component batch than is possible with smaller x-ray beams.

Neutrons record real-time chemical reactions

Neutrons are ideal for studying chemical reactions in real-time without impacting production processes. Different particle size distributions were used to reveal the effect of this important variable on the reaction pathway and kinetics.

Conventional methods like x-ray diffraction were not suitable for in situ analysis of this batch during heating because of the initial size distribution of the batch materials, and of the texturing that occurs during the melting process.

For more information, see the journal paper at

doi.org/10.1111/jace.15977

Contact

Dr. Ke An

Industrial Liaison

kean@ornl.gov