Residual Stress Development in Additively Manufactured Compositionally Graded Superalloy

Scientific Achievement

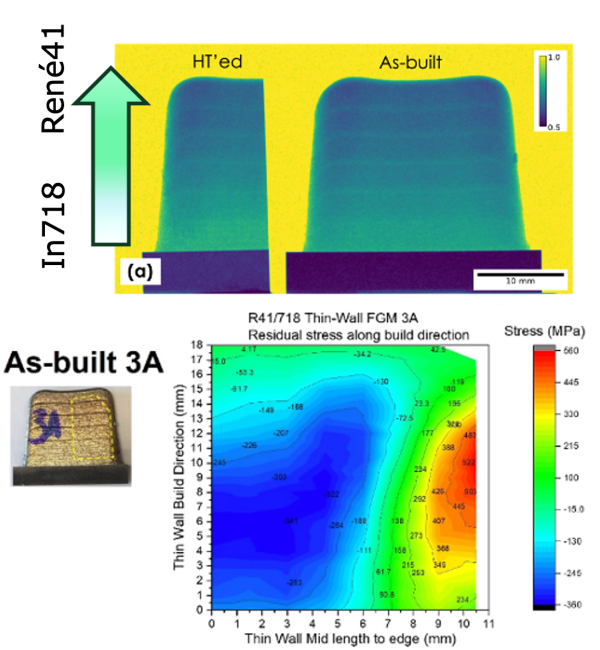

It is shown that the residual stress in additively-manufactured graded superalloy primarily depends on geometry and deposition process and not on composition.

Significance and Impact

The understanding of the residual stress distribution provides input for future simulation and optimization of the additive manufacturing process and material properties, incorporating the influence of thermal history.

Research Details

- A graded superalloy with transition from IN718 to René41 was fabricated by laser blown-powder directed energy deposition.

- Neutron imaging qualitatively visualized the composition variations.

- Residual stress in the built wall was measured by neutron diffraction by computationally resolving the impact of the chemical gradient on the stress-free reference state.

“Residual stress and microstructure in IN718-René41 graded superalloy fabricated by laser blown directed energy deposition,”

Shenyang Huang*, Chen Shen, Ke An, Yuxuan Zhang, Ian Spinelli, Marissa Brennan and Dunji Yu,

Frontiers in Metals and Alloys, 1:1070562, (2022). DOI: https://doi.org/10.3389/ftmal.2022.1070562